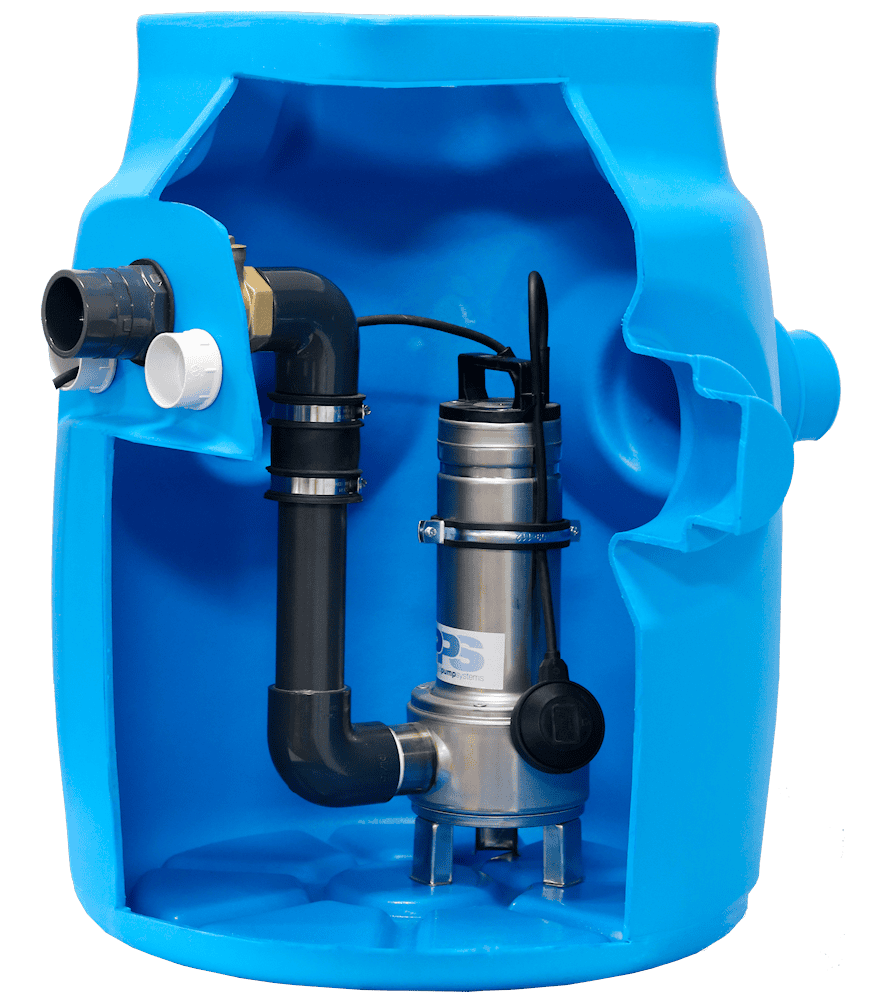

The Foul V3 is a packaged pump station designed to collect foul water from basements and ground floor extensions.

Overview

• Specifically designed for below ground applications.

• A typical application would be the collection and discharge of foul and grey water from a basement fitted with a bathroom and a utility room.

• For kitchen applications, we recommend fitting a grease trap prior to the pump station and do not recommend sinks fitted with macerator type waste disposal units are connected to pump stations.

• The chamber is manufactured from HDPE and able to withstand hydrostatic forces encountered in applications with high water tables.

• Delivered as a complete package including, chamber, all internal pipework and a D10SA foul vortex pump.

• Designed to be installed by contractors with competent building, plumbing and electrical skills.

This pump station is not designed to collect ground water from a cavity membrane system. For this you would require a V-Series packaged pump station, such as a Dual V3 pump station.

| Product Code | F V3 |

| Chamber Material | High Density Polyethylene |

| Volume Below Inlets | 137L |

| Total Volume | 273L |

| Fixed Inlets | 3 x 110 / 160mm |

| Cable Duct Size | 50mm |

| Discharge Connection | 2” / 50mm BSP Class C |

| Discharge Pipework | 2” / 50mm BSP Class C |

| Internal Pipework | 2” / 50mm BSP Class C |

| Cable Duct Pipework | 2” / 50mm White Waste Pipe |

| Vent Pipework | 2” / 50mm White Waste Pipe |

| Pump Model | D10SA |

| Voltage | 230V |

| KW Rating P1/P2 | 1.14/0.75kW |

| Full Load Current | 5.88A |

| Fuse Spur Rating | 13A non-switched |

| Typical Duty | 4.0l/s @6.5m |

| Power Phase | Single |

| Weight | 11.95kg |

- NBS specification R18 (clause 310) Pumping Stations & Pressure Pipelines

- BS 8102:2022 Type C Drainage Protection

The chamber sits on a concrete base, inlets in the form of perimeter channel or modular 110mm system are connected into the chamber, a 50mm discharge pipe connects to the gravity drain and a 50mm cable duct to bring electrics from the chamber into a dry environment. The chamber is vented via a 50mm duct to the same standard as traditional SVP. An air admittance or ‘durgo’ type valve should not be used. The chamber is filled with water to prevent buoyancy and is surrounded with concrete. A simple rule of thumb is the top of the chamber should be level with the structural slab or no deeper than 500mm from the final finishes.

The whole lot should be completed with a double sealed cover supplied by the contractor to tie in with the general floor finish. Remember this product needs to be accessed for service so care should be taken with the location.